Behind the Scenes: The Bean

Curves makes any project more complex. There’s a number of reasons why, but it mostly boils down to equipment and the nature of wood.

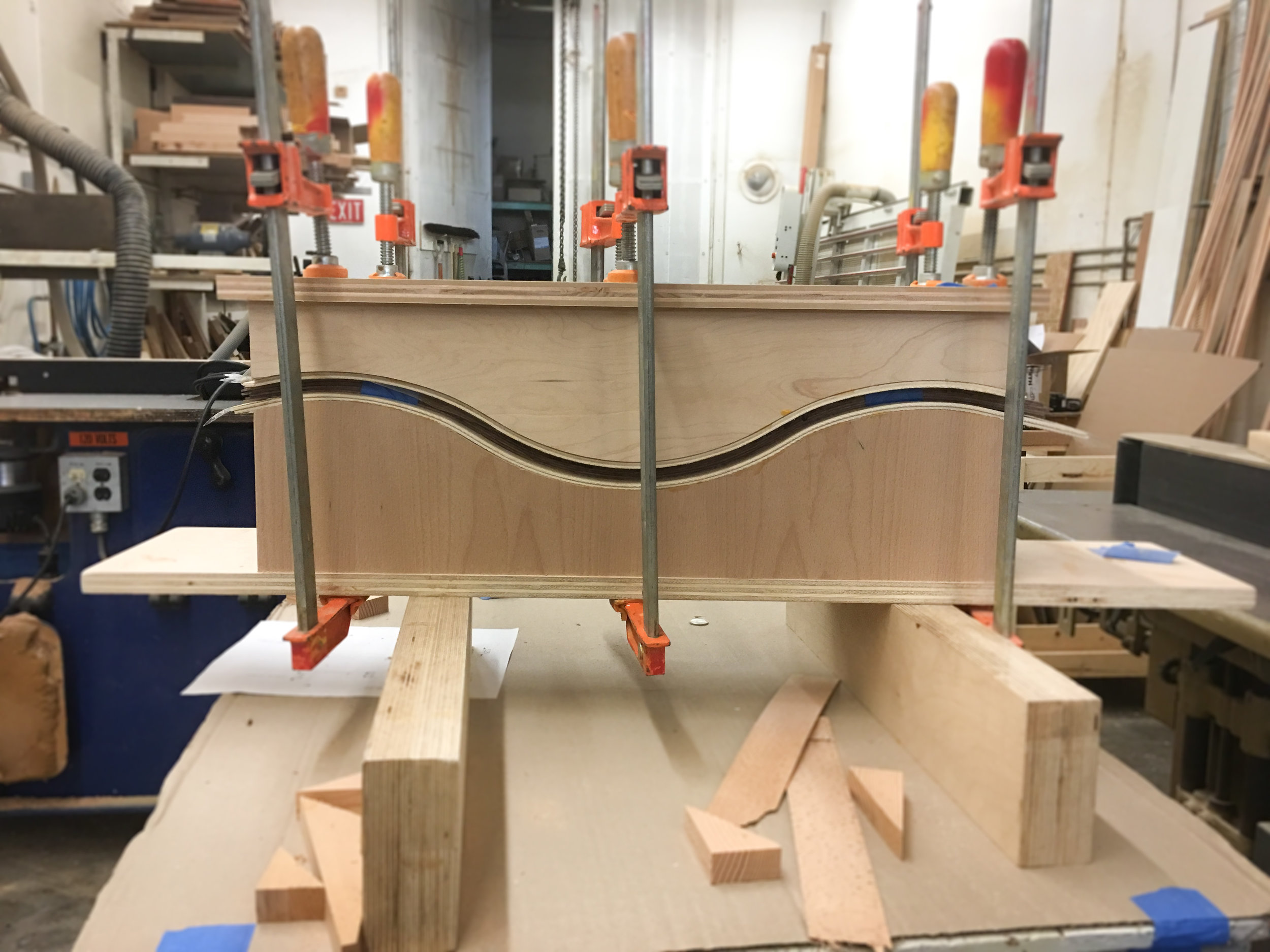

All the machinery in a modern wood shop is designed to handle linear pieces of wood. There are plenty of ways to adapt machinery so that it can accept curves, but those adaptations require lots of customized supports. Instead of just making parts for a desk, you must first build the supports to allow you to make the parts. It’s effectively double the work.

Trees grow *relatively* straight, and thus processed lumber is available in straight segments. Given this reality, there are a couple different ways to make curved pieces from straight stock. Without going down a rabbit hole, I’ll summarize by saying bent-laminations is my preferred method because:

- It allows me to build out of solid wood

- There are no veneers to deal with

- It’s the most structurally stable

The Bean doesn’t just have some curves, it’s only curves. In fact it has both convex and concave curves, which translates into lots of templates, forms, jigs, and tests. Heres’ a closer look at what went in to making The Bean.